Technical solutions

Different technical solutions can be applied for the production of the membrane switches, according to the customer’s requirements and application.

SILK-SCREEN PRINTING

Topflight keyboards can be produced with graphics printed in any design and colour. This design freedom allows choices from simple matt colour messages to elaborate many colour process images. Sub-surface printing affords protection for the life of the keyboard to the use and the scratches. Topflight Italia can print any colour included in Pantone and RAL catalogue or specific tonalities required by the customer. Thanks to the use of the spectophotometer, a particular equipment able to read the sample colour, the relative ink formula can be elaborated to obtain the requested tonality.

DIGITAL PRINTING

For quick prototypes or production of low quantities, the digital printing is the perfect choice. This solution eliminate the traditional equipment, saving tooling costs. In addition it allows the half tone printing with a very high resolution.

MATERIALS FOR THE AESTHETIC LAYERS

For a high quality product, only high quality and tested materials are used, in order to guarantee a long life membrane switch. The choice of the material is done according to the keyboard application.

The materials are the following:

- POLYESTERE

- Fine-textured

- Gloss antiglare

- Semi-gloss antiglare and anti-scratch

- Antimicrobic with treatment for uv rays

- POLYCARBONATE

- Gloss

- Matt

- Antiglare and anti-scratch

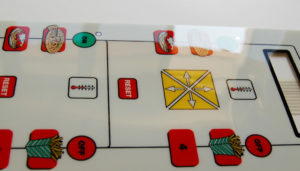

BACKLIGHTED WINDOWS DISPLAYS AND LENS DOTS

It is possible to realize some transparent areas that allow to see the parts below. In this way we can obtain transparent or coloured windows for displays (transparent red, green, light blue, clear grey) and backlighted keys both with traditional systems and with SMD LEDs embedded in the membrane switch. In addiction this effect can be produced in two ways:

- dead-fronted effect

- colour changing effect

Moreover, a special anti-reflection and scratch-proof treatment called “texturing” is usually made by Topflight. The structure of the polycarbonate or polyester aesthetic layer is modified and hardened through this process, thanks to a special machine in presence of nitrogen, which assure the quality and life of this treatment.

The window areas can be “dead-fronted” and appear transparent and visible only when backlighted.

EMBOSSING

On request, Topflight switches provide positive sensory feedback to the user through the embossing or debossing techniques on the surface material. This option accents the key or switch areas by providing discreet perimeters of both raised edges and raised surface areas. The printed characters on the surface of the keys may also be embossed or debossed. This technique allows to produce also membranes switches for blind people utilizing the “Braille” alphabet. This process is carried out by Topflight through a special and exclusive system, in order to assure the greatest quality and long life.

EMBEDDED SMD LEDS

When there is no room on the electronic card or saving time during the assembly of the components is important, Topflight supplies keyboards with SMD LEDs directly embedded in the circuit of the membrane switch. They are available in various colours and with different light power . The standard colours are the following: yellow, red, green, blue, orange. In order to reduce the thickness of the membrane switch and to improve the diffusion of the light, the lens dot of the aesthetic layer over the LEDs is embossed. However, the SMD LEDs can be embedded in the membrane switch without embossing the aesthetic layer. In this case the thickness of the membrane switch is higher.

KEYS WITH TACTILE FEEDBACK

Membrane switches with tactile feedback can be supplied on request. According to the final application, the switches can be realized in two different tactile feedback: snap domes tactile feed-back; bubble tactile feed-back.

Metal snap domes tactile feedback

Specific triangular metal snap domes, made of stainless steel, are embedded under the key.

Bubble tactile feedback on one circuit (cheaper solution)

It is obtained by embossing the key. The contact is realized directly under the aesthetic layer.

Bubble tactile feedback on double circuit (more reliable solution)

It is obtained by embossing the key. The bubble feedback is on the aesthetic layer, while the contacts are on a specific circuit below.

SLIDE-IN POCKETS

In order to personalize the membrane switch, some pockets are made, also over the keys, to slide in changeable labels, as for example words and logos. This solution enables to create a standard membrane switch with pockets to slide in multi-language texts or multi-logos. This allows to reduce the production costs. For the custom labels, a plastic film (polycarbonate) or a thin cardboard is suggested.

The slide-in pockets can be realized in two systems:

- Outside pockets

The label is slided-into the membrane switch through an external slot placed on the outside edges or on the rear of the membrane switch. The label can be replaced at any time, even if the membrane switch has already been applied on its support. - Inside pockets

A pocket is realized inside, without any connection with the outside. In this case the membrane switch is supplied with the aesthetic layer partially assembled, in order to allow the sliding of the label by the customer, who will provide, then, to seal completely the aesthetic layer once the operation is completed. When slided in, the label can’t be removed any more.

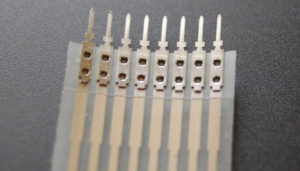

CONNECTORS

Are usually provided the membrane switches with connectors:

- female connector – pitch 2,54 mm – with plastic housing

- male connector – pitch 2,54 mm – with plastic housing

- solder connector

alternatively the terminals of the traces are left uncovered for ZIF connectors.